11 Dec 2020

Anval Confirm the Dexterity of the RFS Valve

By Team Anval

Rotary Floating Shoe valveshighly durable has further demonstrated its flexibility through its the successful application in Brightwater’s Biomass processing plant When Brightwater Engineering was awarded the contract for an AU$8.5m plant expansion project at new Perth in Western Australia, there were many complex aspects of the project that they had to consider. The Biomass was to be fed simultaneously through two identical injection systems supplying furnaces which were used for power generation. Critical to the plants' success was the ability to isolate the different areas of the injection system, the maintenance of an airlock around the furnace whilst maintaining a continuous supply of feedstock and, on top of this, high wear-resistant equipment with the ability to handle difficult materials. Anval was approached to provide engineering advice and support to the Brightwater team in regards to the most applicable equipment for this project. Anval's Floating Shoe technology in its RFS Valves has been serving some of the most demanding industries as an airlock and metering device for over a decade. Drawing from the vast experience within the materials handling industry we were able to recommend the high wearing Rotary Floating Shoe Valves for this challenging application.

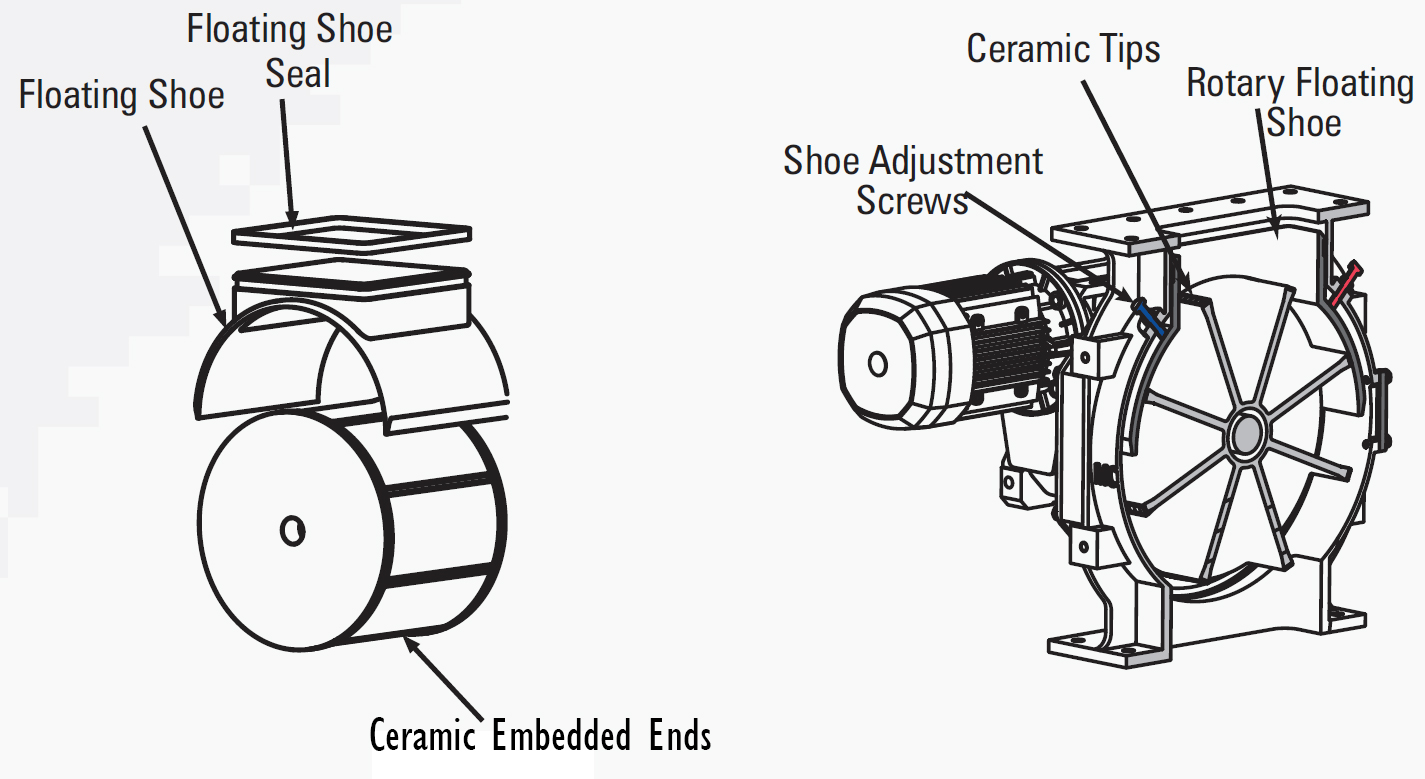

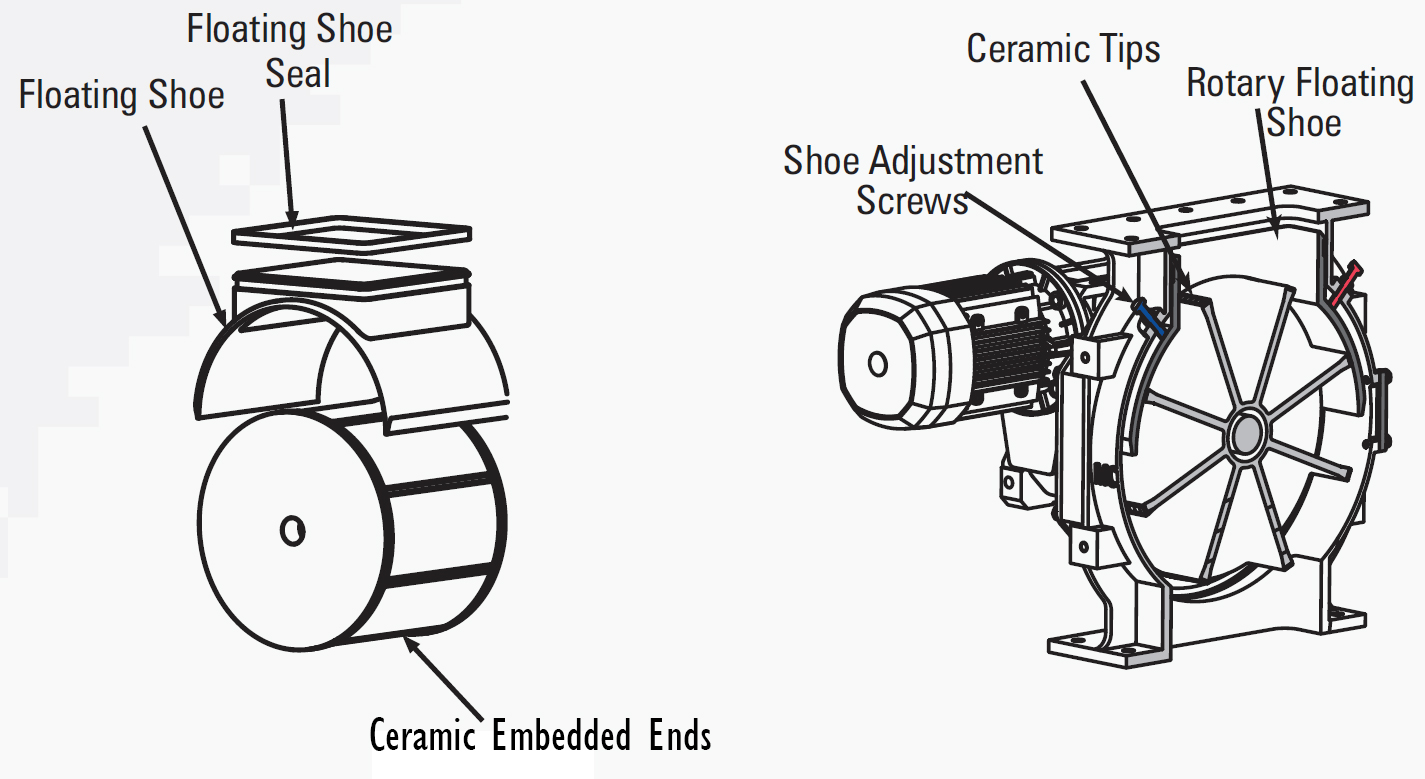

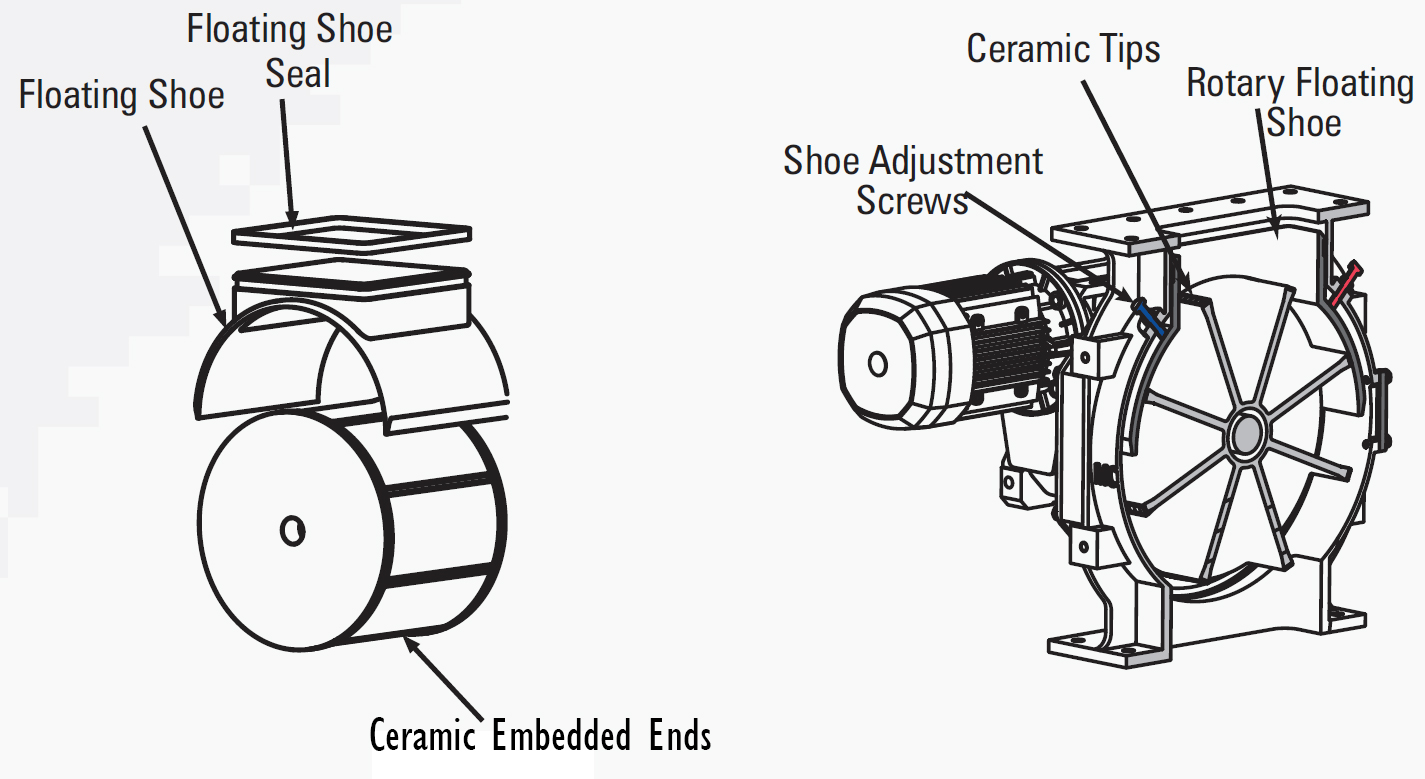

The Anval RFS valve is designed in a manner that creates additional sealing performance through the use of a ‘Floating Shoe’. This is where the ceramic embedded rotor ends create a seal with an adjustable shoe as opposed to the body; as the shoe wears, the seal can be maintained by adjusting the external bolts to push the shoe against the rotor. This mechanism completely avoids wear in the body and, therefore, an increased level of consistency and performance throughout the extended life of the RFS valve.Anval also recommended the use of its SG Series Slide Gate Valve to work in collaboration with the RFS and allow for the effective isolation of the unit for maintenance to the furnace. Based on the figures provided by Brightwater, Anval determined that the most appropriate sizing for this application would be the RFS750 paired with the SG750.