08 Sep 2020

Anval Increase Efficiency and Reduce Downtime for Tata Steel, UK

By Team Anval

Anval provide a long term solution to on-going operational issues at Tata Steel’s Scunthorpe Works in UK by using simple and robust design solutions Anval is constantly developing and widening their range of equipment to cater for the ever-increasing demands of their customers’ process optimization. While most industries routinely handle powdered substances en-mass, each material will have specific needs that will need to be tailored to ensure efficiency is maintained. Anval prides itself on using simple and robust design solutions to effectively fulfill customers’ performance requirements.

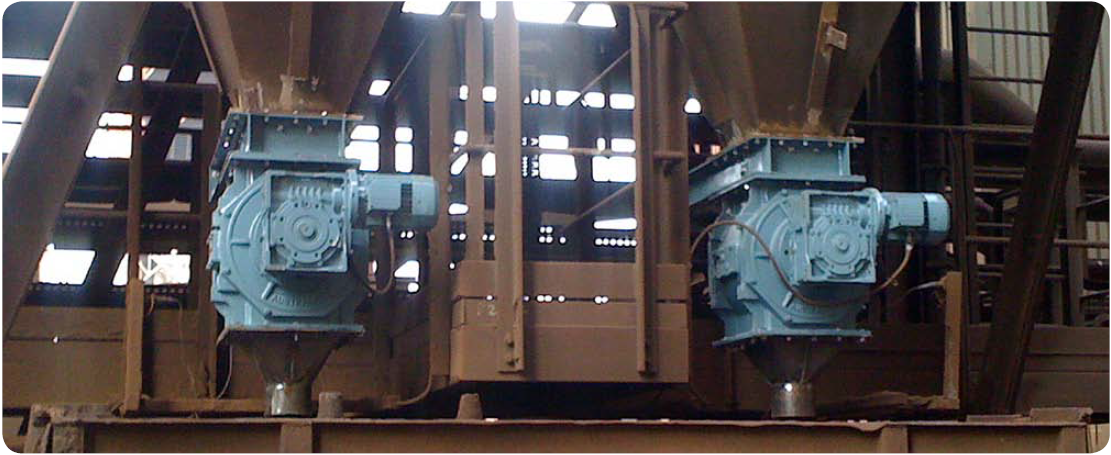

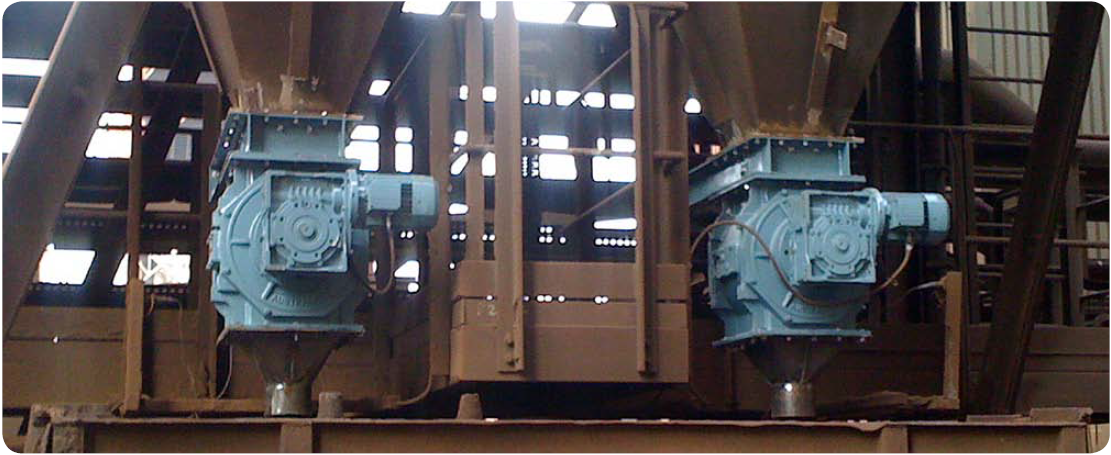

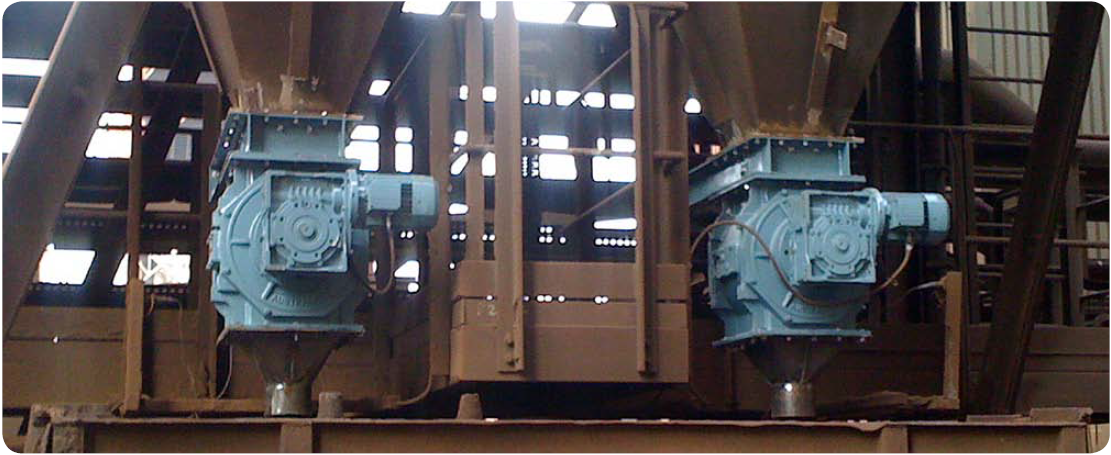

To this end, Anval was recently approached by Miss Paula Saxby of Tata Steel in Scunthorpe, UK. Miss Saxby requested a long term technical solution to an on-going operational issue at the Scunthorpe Steel site; the manufacturer of the existing valves would, or could not provide any spare parts or even a site visit to help with the troubleshooting of operational issues.The valves where being used to manage the flow of fly ash from a large furnace; there were 12 Rotary Valves in operation, each sitting below a Filter Bin. This number of valves allowed for a certain degree of failure, with other bins able to compensate for the extra flow through, however, the valves could only be worked on during a furnace shut down period. Each Filter Bin was also fitted with a high-level sensor that would detect an excessive level of fly ash and trip out the furnace, the fewer valves in operation; the sooner the furnace would be tripped.

The valves in use would break down or cause the furnace to be tripped, on average, 4 times a month; each furnace shut down was estimated to cost Tata Steel between £8,000 and £10,000.With this in mind, Anval’s technical team put forward the suggestion that Tata Steel implements the use of an SL Series Slide Gate Valve above the Rotary Floating Shoe Valve; in this case, the SL300M was the correct fit with RFS 250 Size. This set up would allow the cessation of flow through the RFS valve for a maintenance period whilst the furnace was still in operation. Though this set up does not allow an infinite maintenance period, it does allow for minor repairs and servicing where the previous system did not (approximately 8 hours in this case). Anval’s competitive pricing of this highly durable valve was the icing on the cake for Miss Saxby with the first order for 2 of each valve being placed shortly after our first site visit and a planned rollout of 12 such valve combinations for the fly ash management system based around this large furnace.