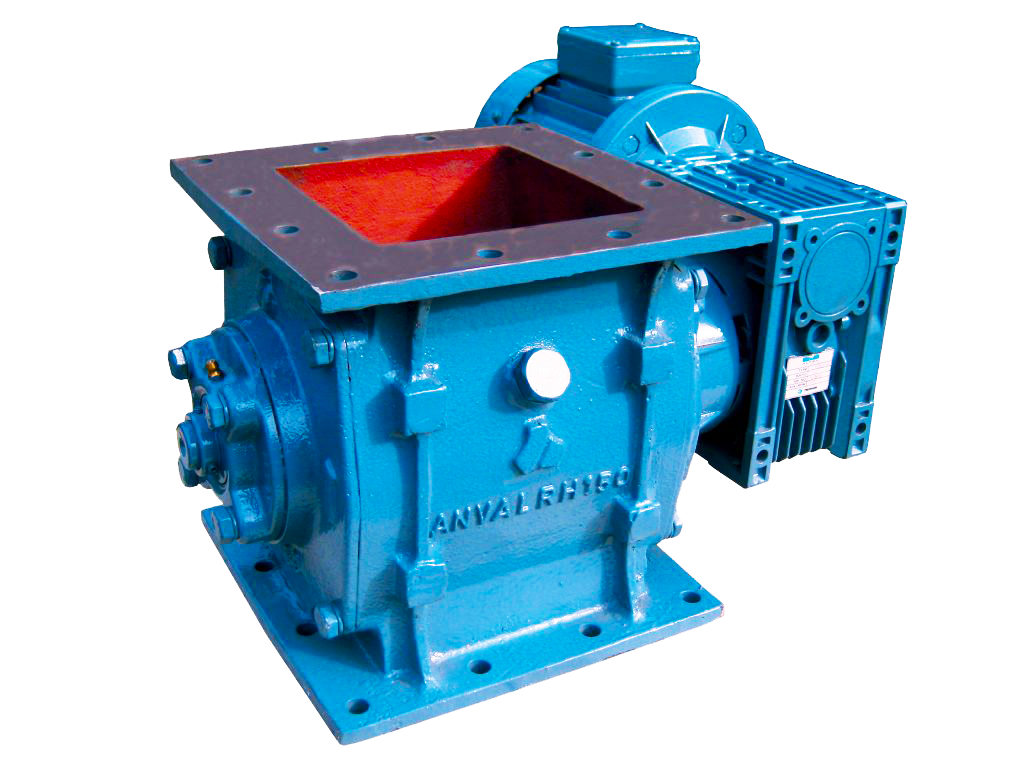

Description

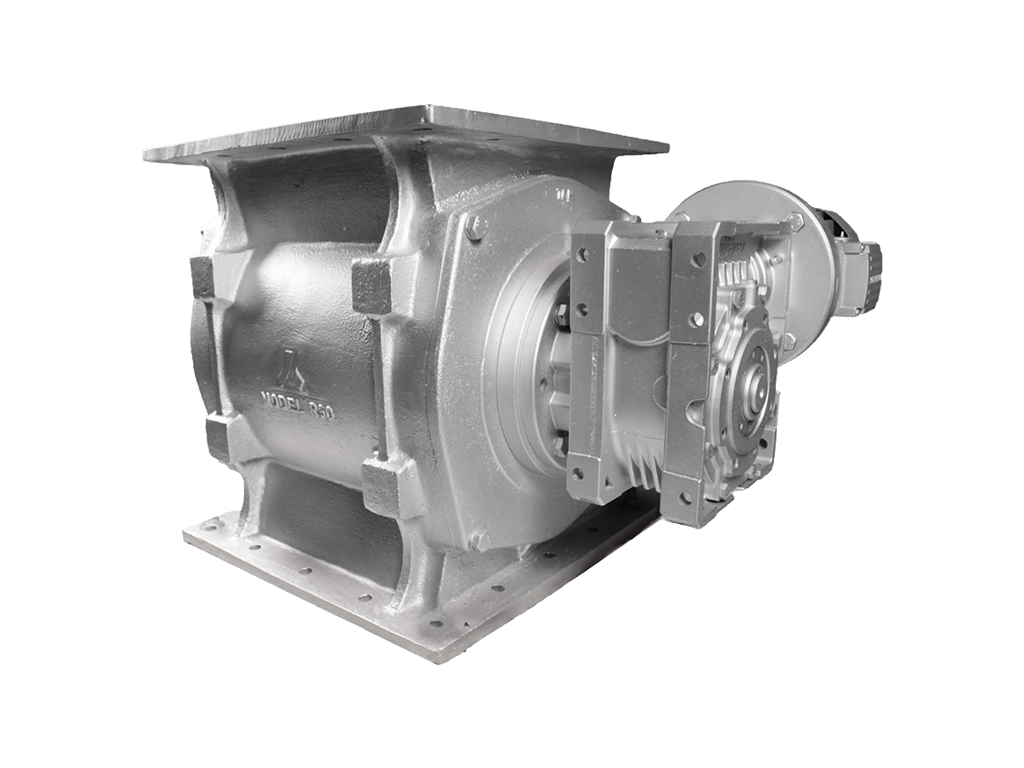

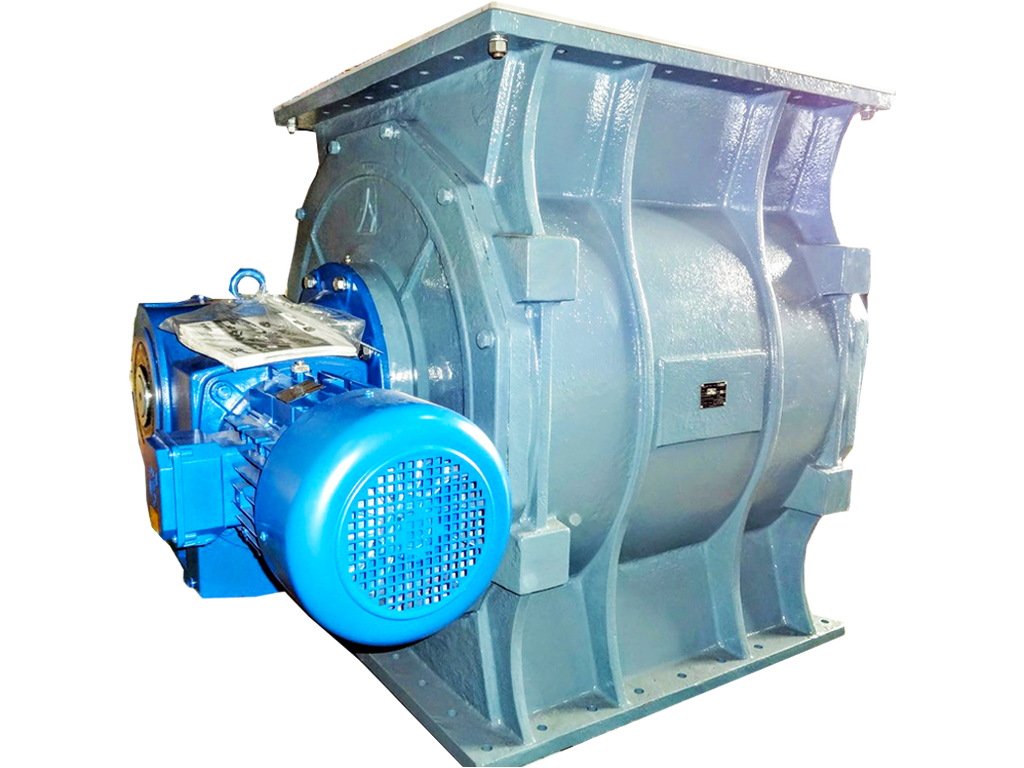

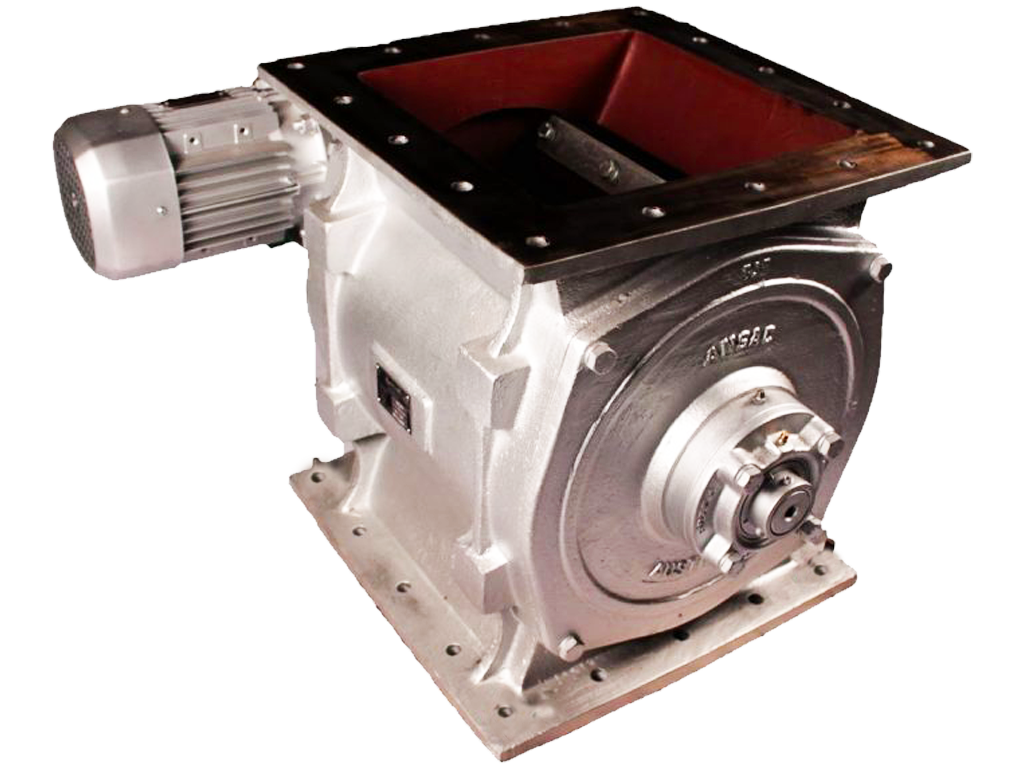

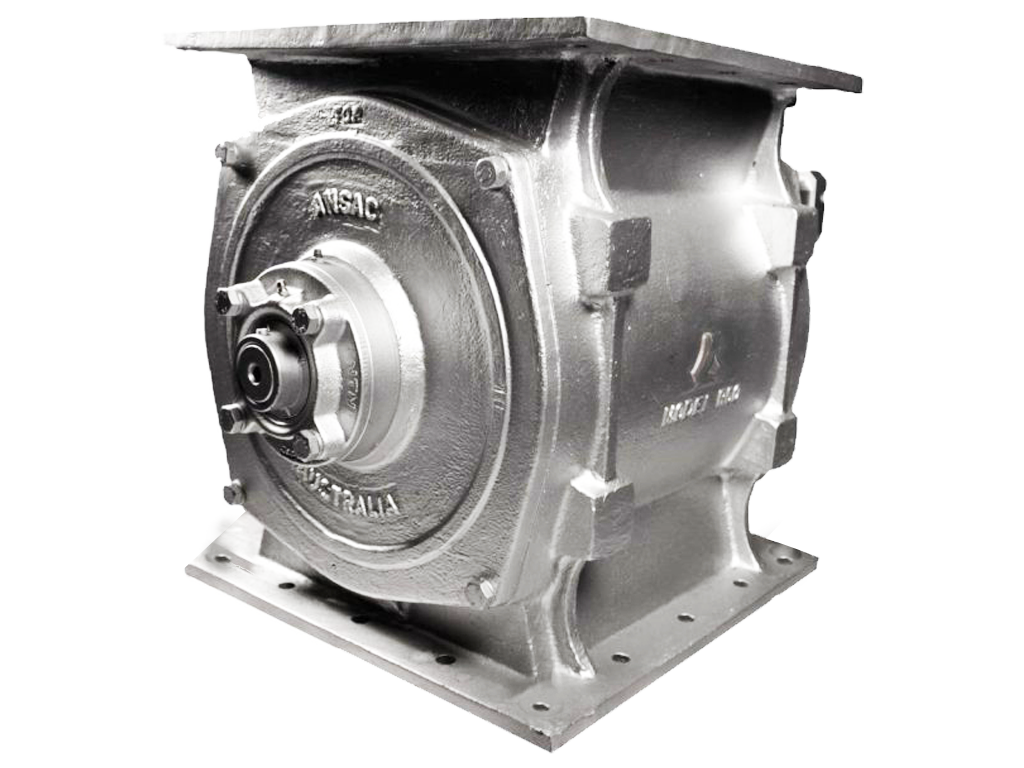

The ATEX Rotary Airlocks & Feeders Certified Heavy Duty Airlocks for use in Explosive Atmosphere RHX Series ATEX Rotary valves are designed for use in a wide range of applications from heavy mineral lumps to light dust. Unlike our competitors, the RHX Series valves are in single piece cast construction reducing the number of seams for wear. These valves operate under the toughest conditions with minimal maintenance.

The “labyrinth seals” ensures perfect sealing of rotating shaft thus ensures zero leakage through shaft ends. These labyrinth seals even effective with highly abrasive products and also when there is high pressure across the system.

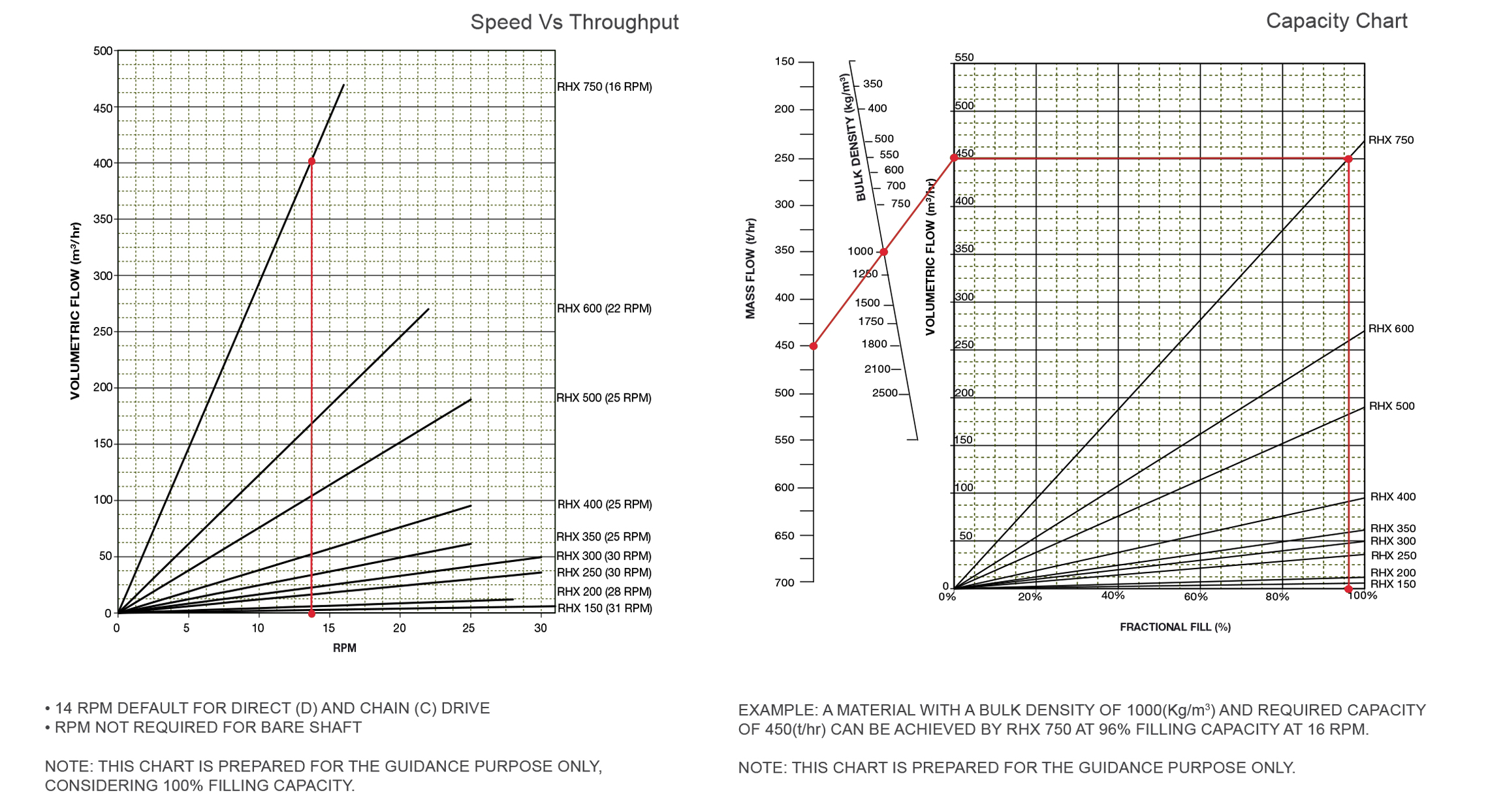

These valves have all of the advantages of Cast Iron over traditional mild steel including superior corrosion resistance, better wear properties and thermal stability. RHX series ATEX Rotary Airlocks & Feeders valves are also available in Cast Steel, other alloys to deal with high temp, high wear and high-pressure environments; regardless of the application required. RHX series valves are available in opening sizes from 150mm – 750mm and also available in Direct driven, Chain driven or in Bare Shaft arrangement. These valves can also be customized to suit the specific application requirements. These valves are best suitable for industries ranging from Chemicals, Food, Steel, Cement, Wood, Power to Mineral processing plants where the environment is potentially explosive. All the Mechanical, Electrical and Electronic components fitted in RHX Series are ATEX product certificate.

Configure the valve to your application