Description

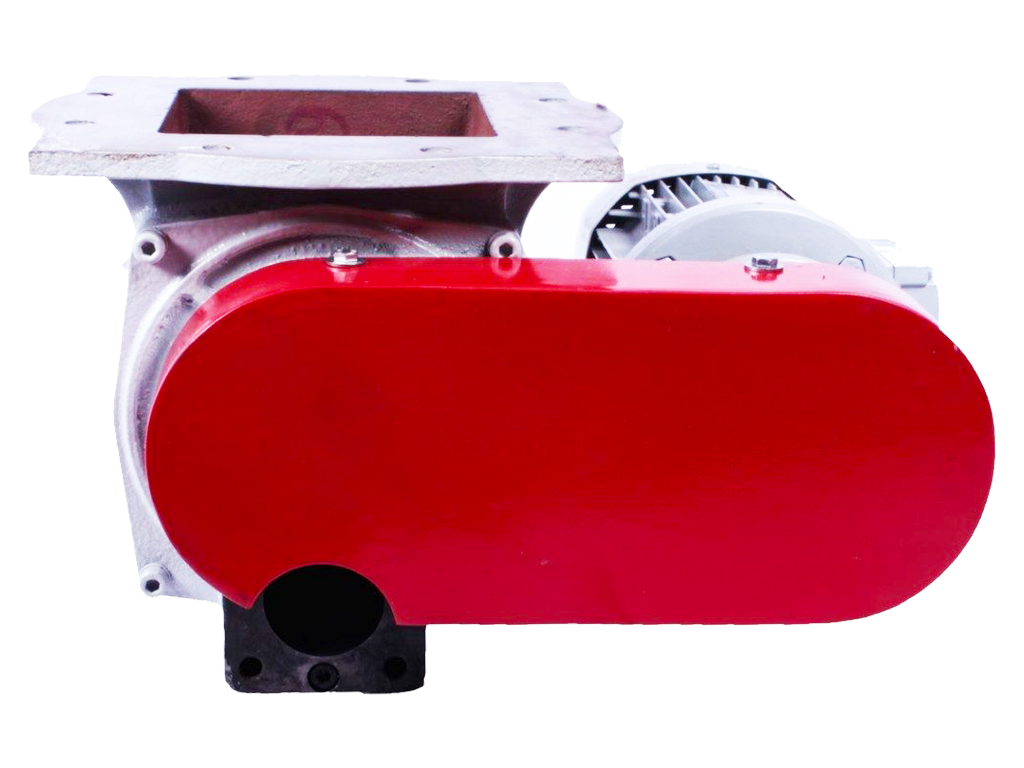

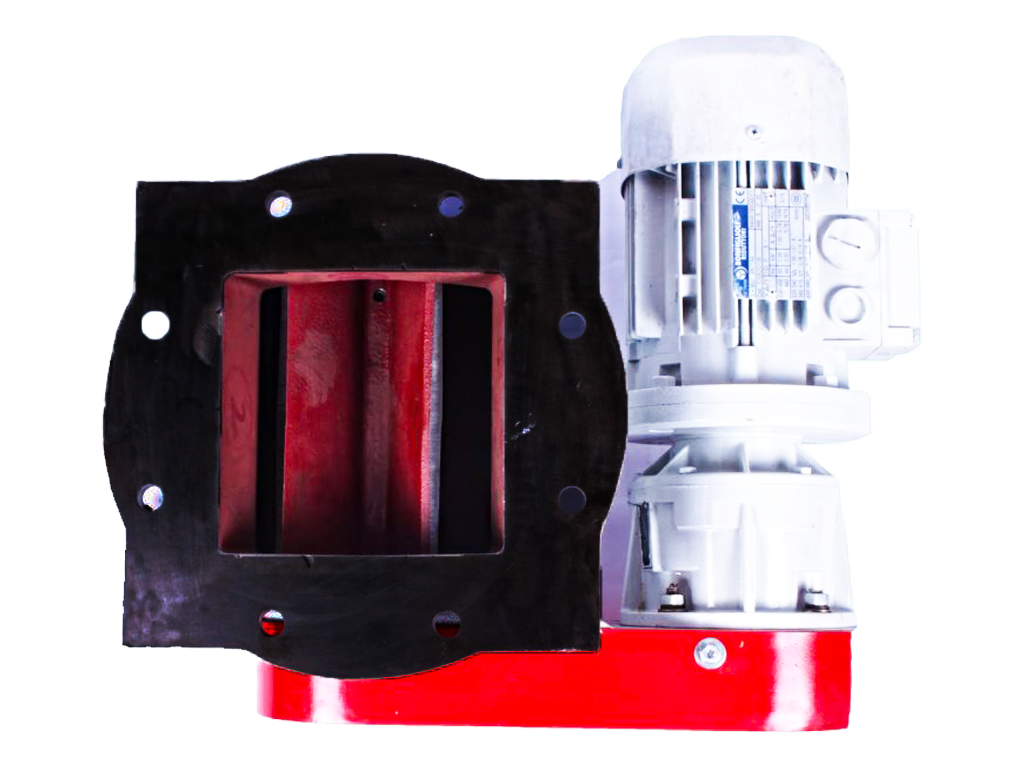

The Blow Through Valves for Pneumatic Conveying Applications The BH Series valve is specifically designed for pneumatic conveying systems, and best suited to non-abrasive products; this is a highly efficient valve that ensures the smooth flow of materials whilst significantly diminishing a loss of pressure.

BH Series Blow Through Valves are in Single Piece Cast Iron construction with internal surfaces machined to high precision, ideally suited for pneumatic conveying applications; best suitable for food, flour, grain, plastic, chemical, pharmaceutical and milling industries.

These valves are CE marked and designed in compliance with the provisions of all applicable Health & Safety Requirements across the globe. The BH Series rotors are perfectly designed and manufactured to have a close radial and axial clearance of 0.10 mm (max.) for better air locking. The “labyrinth seals” ensures perfect sealing of rotating shaft thus ensures zero leakage through shaft ends. These labyrinth seals even effective with highly abrasive products and also when there is high pressure across the system. BH Series valves are available in opening sizes ranging from 150 mm to 350 mm with Universal Flanges to suit both Square and Circular mating flanges. These valves are not only robust, rigid and durable but can also be customized to the specific requirements of a given application.

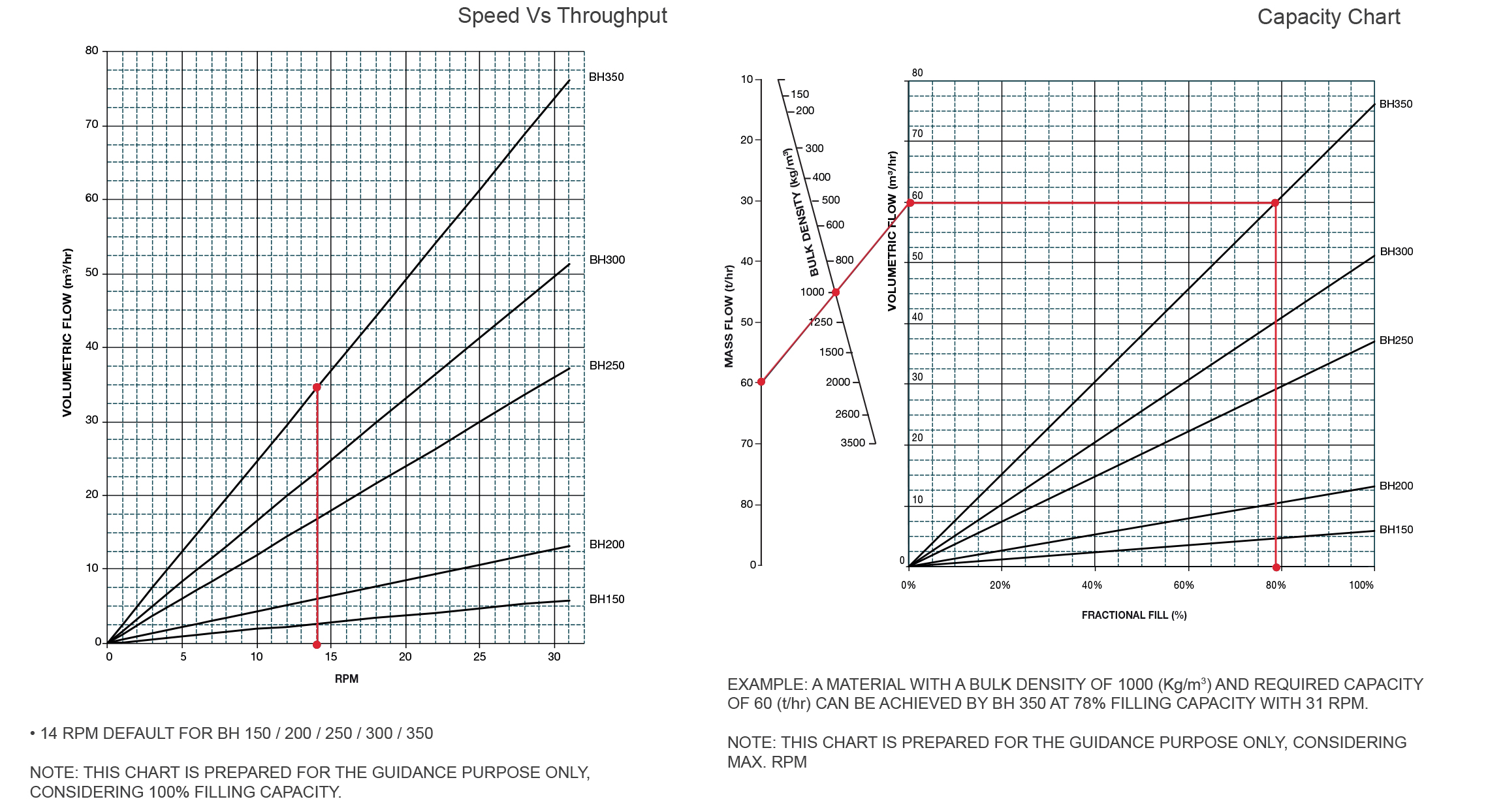

Configure the valve to your application