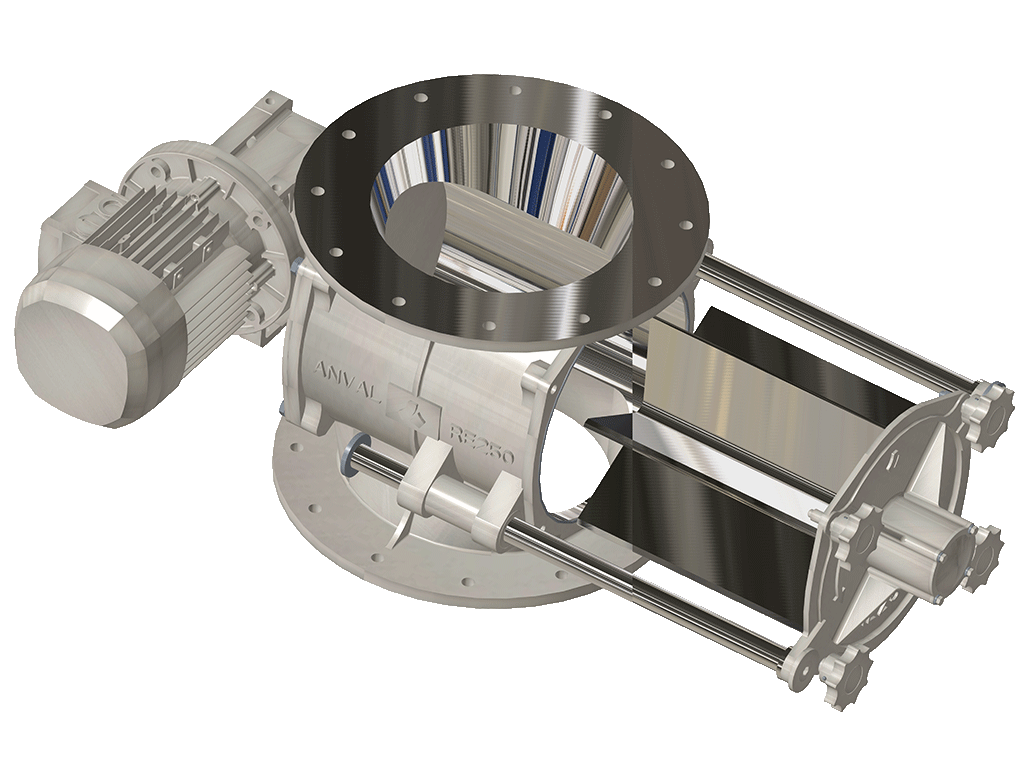

Description

Tool-Less Quick & Easy Clean Rotary Valves airlock for dairy applications where frequent & quick cleaning of valve internals is necessary.RE Series valves can be used for contamination-sensitive applications where frequent disassembly and cleaning is required. All RE Series valves are specifically suited for hygienic Dairy, Food, and Chemical applications.

The RE Series Easy Clean Rotary airlock permit Safe & Tool-less removal of the internal components as one single piece for quick and easy cleaning. This eliminates time-consuming steps during opening and reassembly of internals instead of spending a long maintenance time. Upon reassembly, the Rotor and engages automatically without any complex adjustments and it maintains the original clearance values.

These rotary airlock valves are fully Cast Single piece Stainless Steel construction, by Lost-wax process, with Mirror Finish internals and surface machined to high precision to prevent corrosion, rust or stain and free of dead spots to keep the material without contamination. The Mirror Finish internals helps the cleaning process easier, effective and convenience in cleaning, thus increasing operational efficiency while handling Sticky, Cloggy, and Hygroscopic applications. The “labyrinth seals” ensures perfect sealing of rotating shaft thus ensures zero leakage through shaft ends. These labyrinth seals even effective with highly abrasive products and also when there is high pressure across the system. The RE Series rotary airlock valves are available in opening sizes ranging from 150 mm to 300 mm with Circular flanges. The rotors are perfectly designed and manufactured to have a close radial and axial clearance of 0.20 mm (max.) These valves are CE marked and designed in compliance with the provisions of all applicable Health & Safety Requirements across the globe.

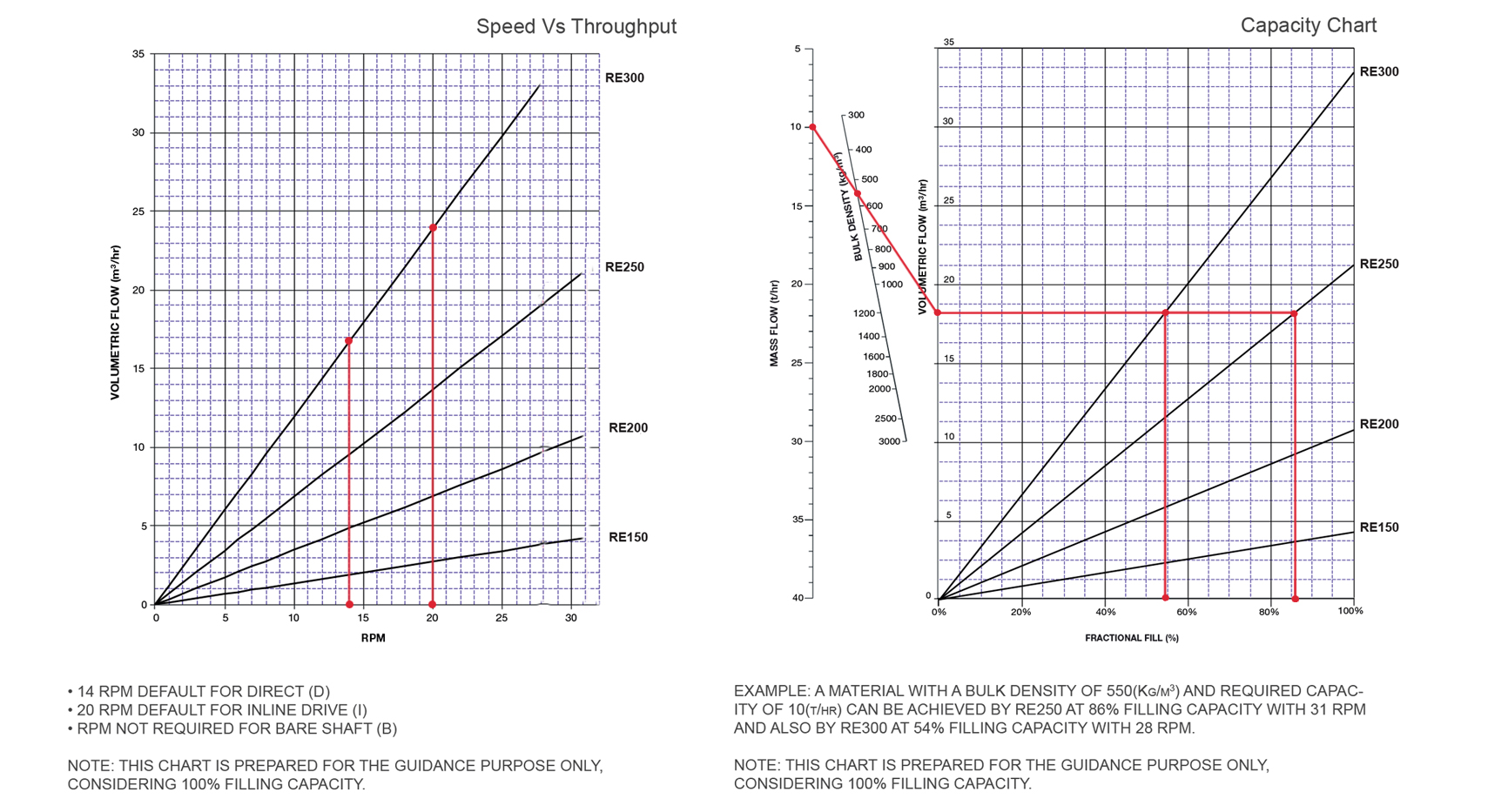

Configure the valve to your application