Description

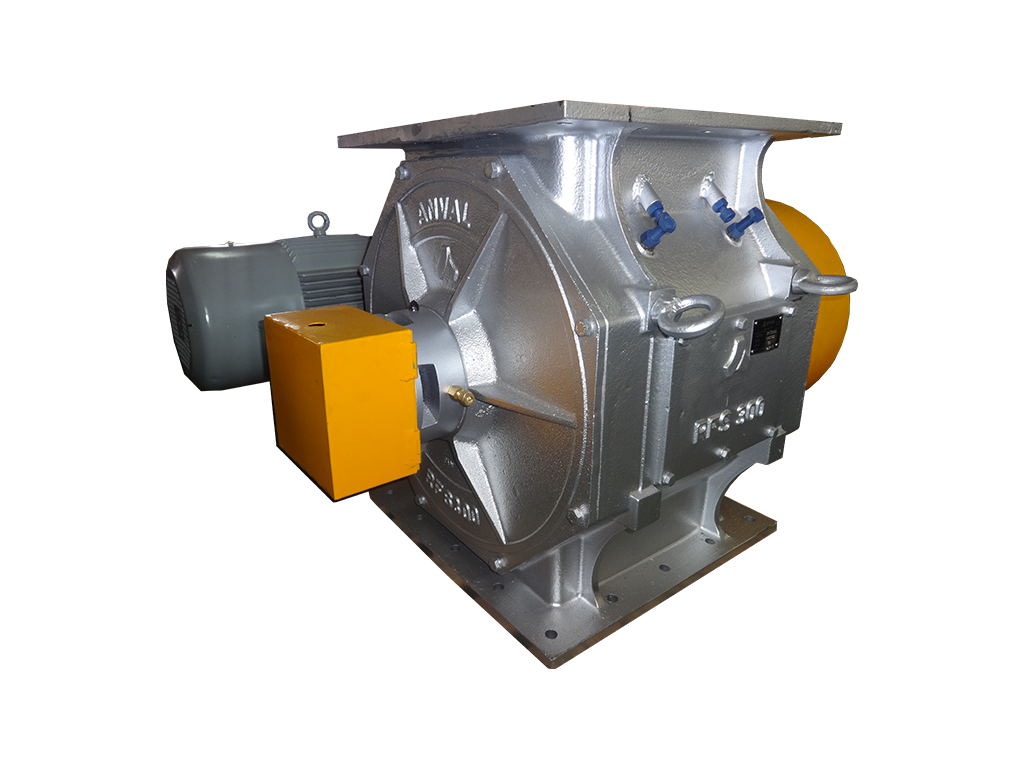

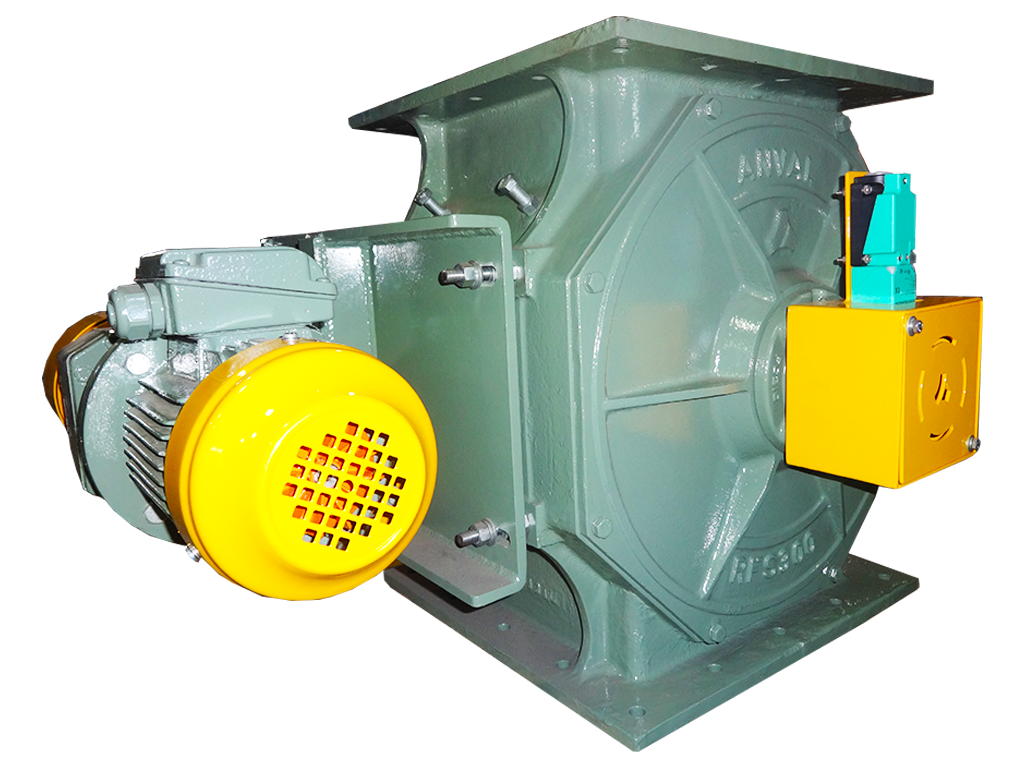

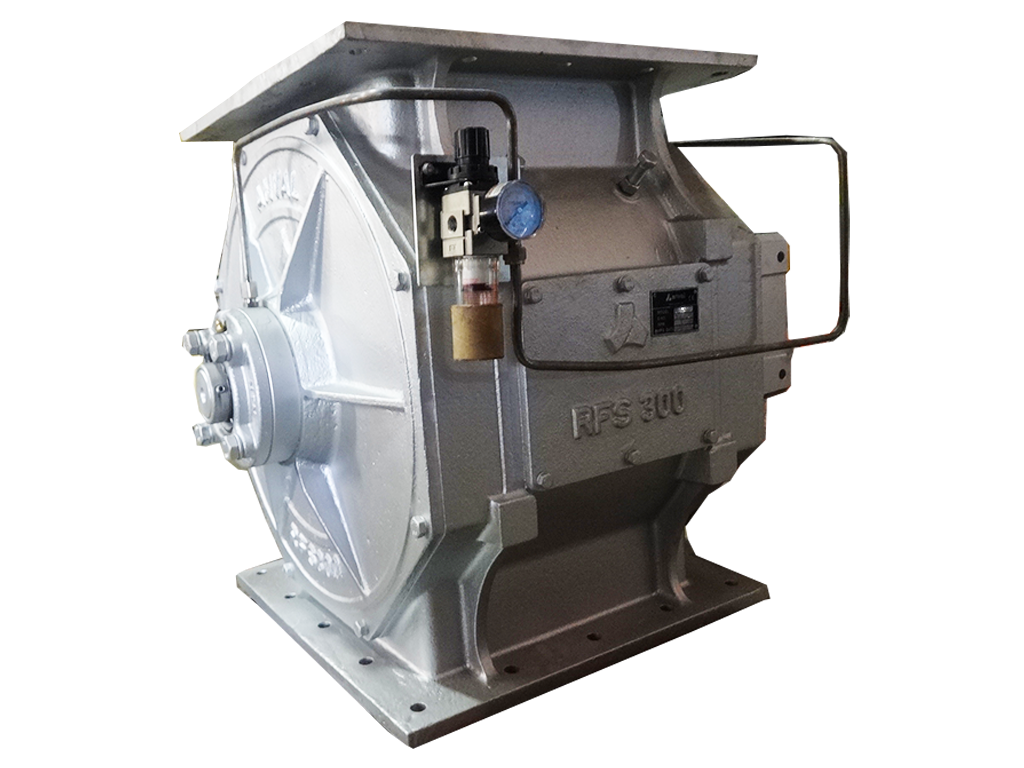

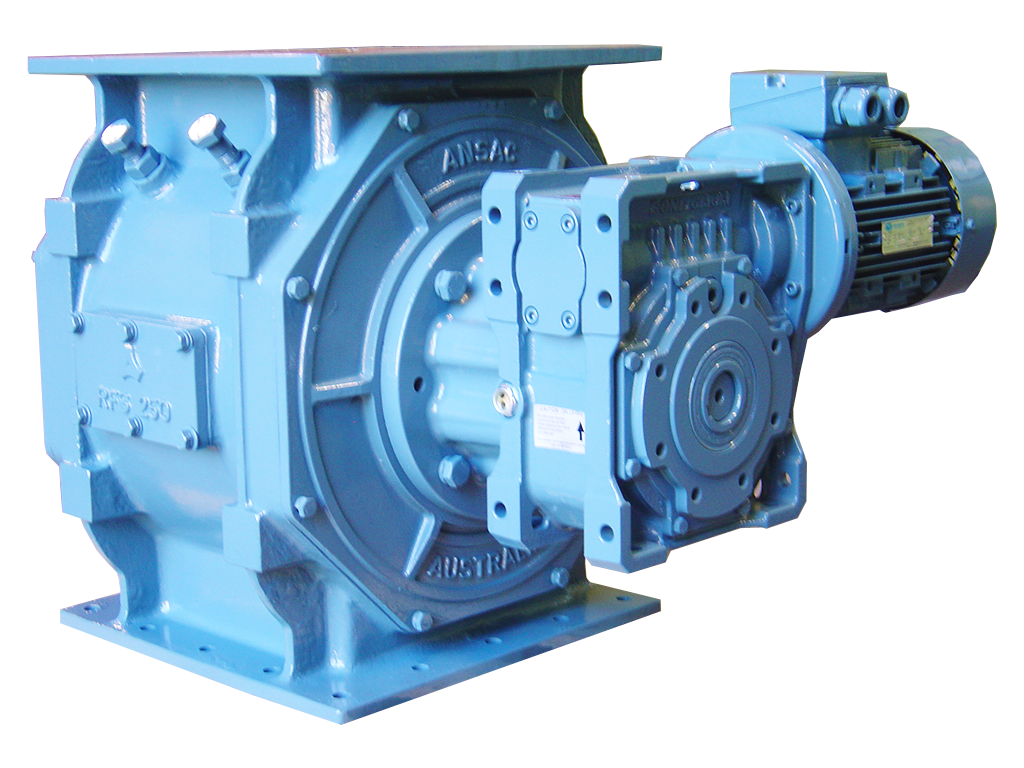

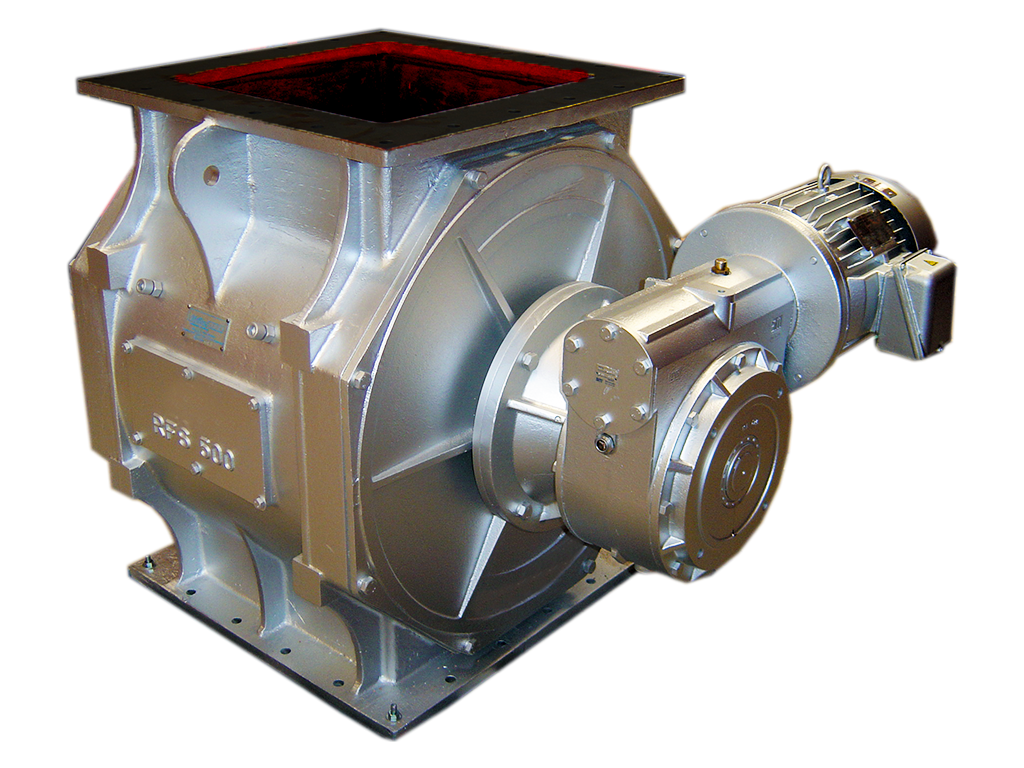

Rotary Floating Shoe valves Or Metering Solution For High Wear, High Temperature and High-Pressure ApplicationsRotary Floating Shoe valves (RFS) provide unmatched performance as airlocks in high wearing applications. The RFS series can last up to four times longer than conventional rotary valves and offers an unparalleled value when handling high wearing products such as Alumina, Iron Ore, Cement, Coal, Fly-Ash and Mineral Sands.

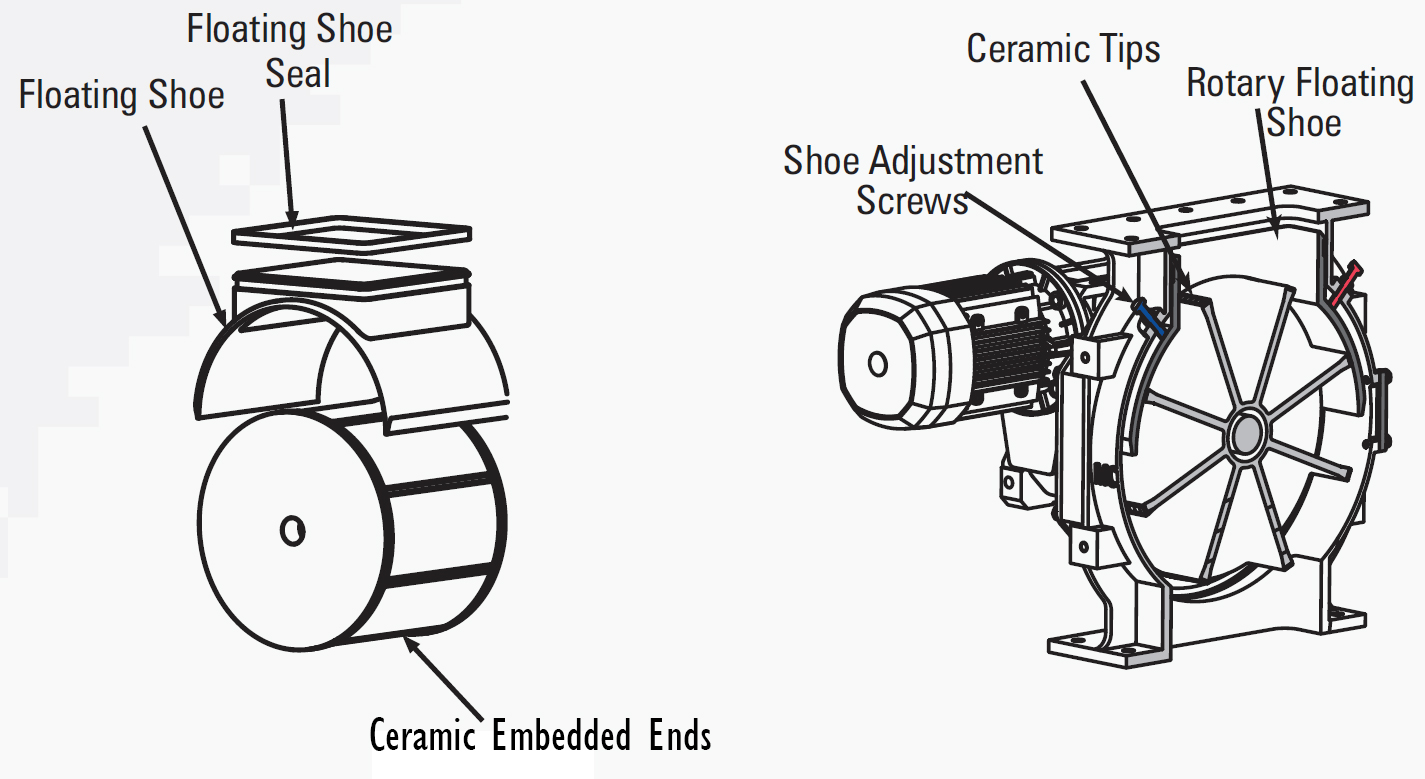

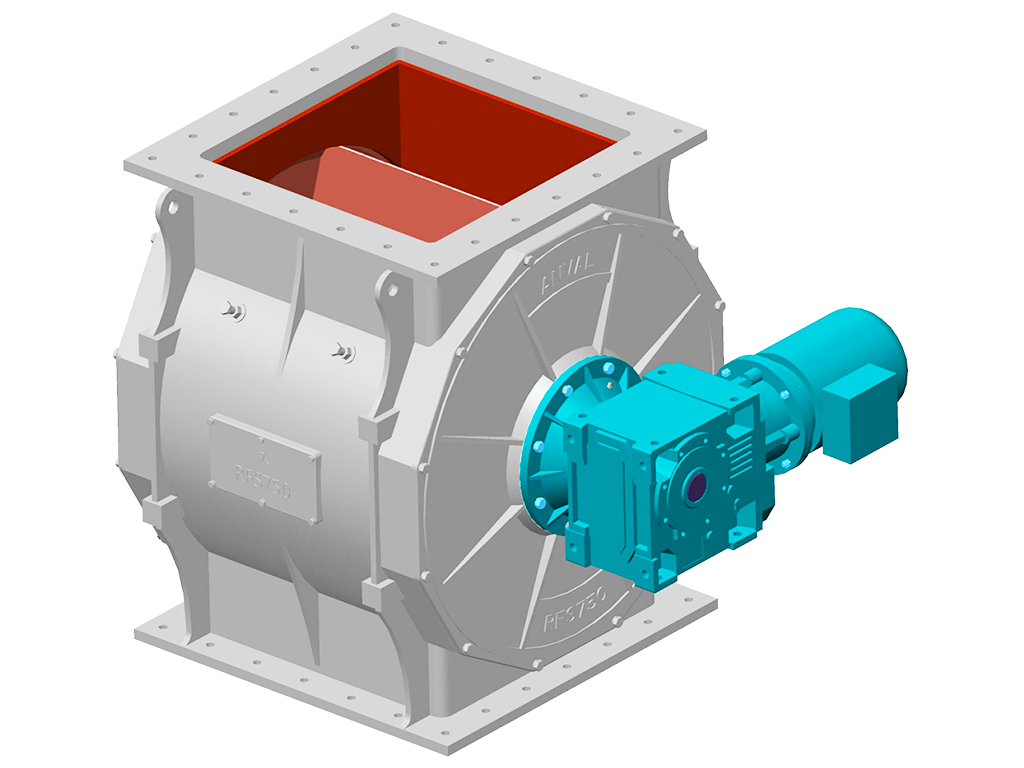

To achieve 100% positive sealing, the Rotary Floating Shoe valves Series valve has a “FLOATING SHOE” which slides tightly into the main body top port flange and rides onto the rotor by gravity force; the contact surface between the two parts forms a mechanical seal leaving a clearance in microns. The sacrificial, hardened SG Iron adjustable shoe can handle up to 10mm of wear and can be adjusted externally while in operation to maintain a minimum clearance in microns at all times.

These valves are designed to require very little maintenance over their service life. The long service life that distinguishes Rotary Floating Shoe valves valves from all other valves in the market is achieved through the ceramic embedded rotor ends in all leading surfaces of the blades and end plates of the rotor.

The School of Mechanical Engineering at the University of Western Australia carried out a series of rigorous wear tests on Anval’s Rotary Floating Shoe valve range focusing on the Ceramic and Spheroidal Graphite Iron interface and concluded that the “RFS Valves can be used to transport even the most aggressive product and still, have a lifecycle of years instead of months”

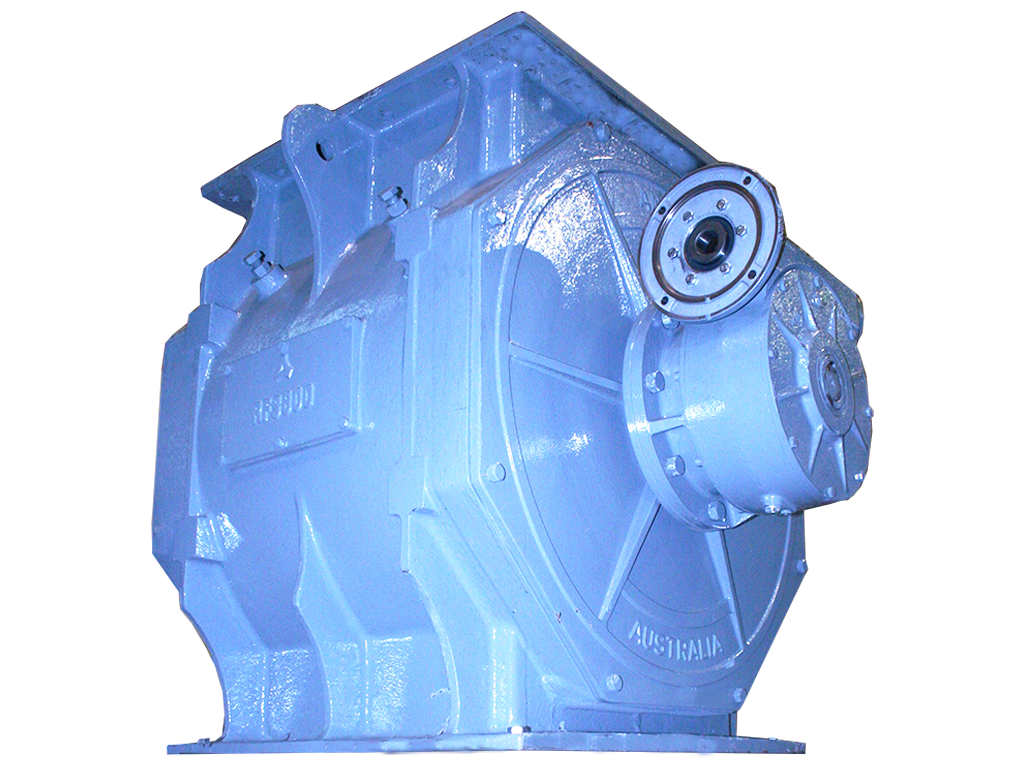

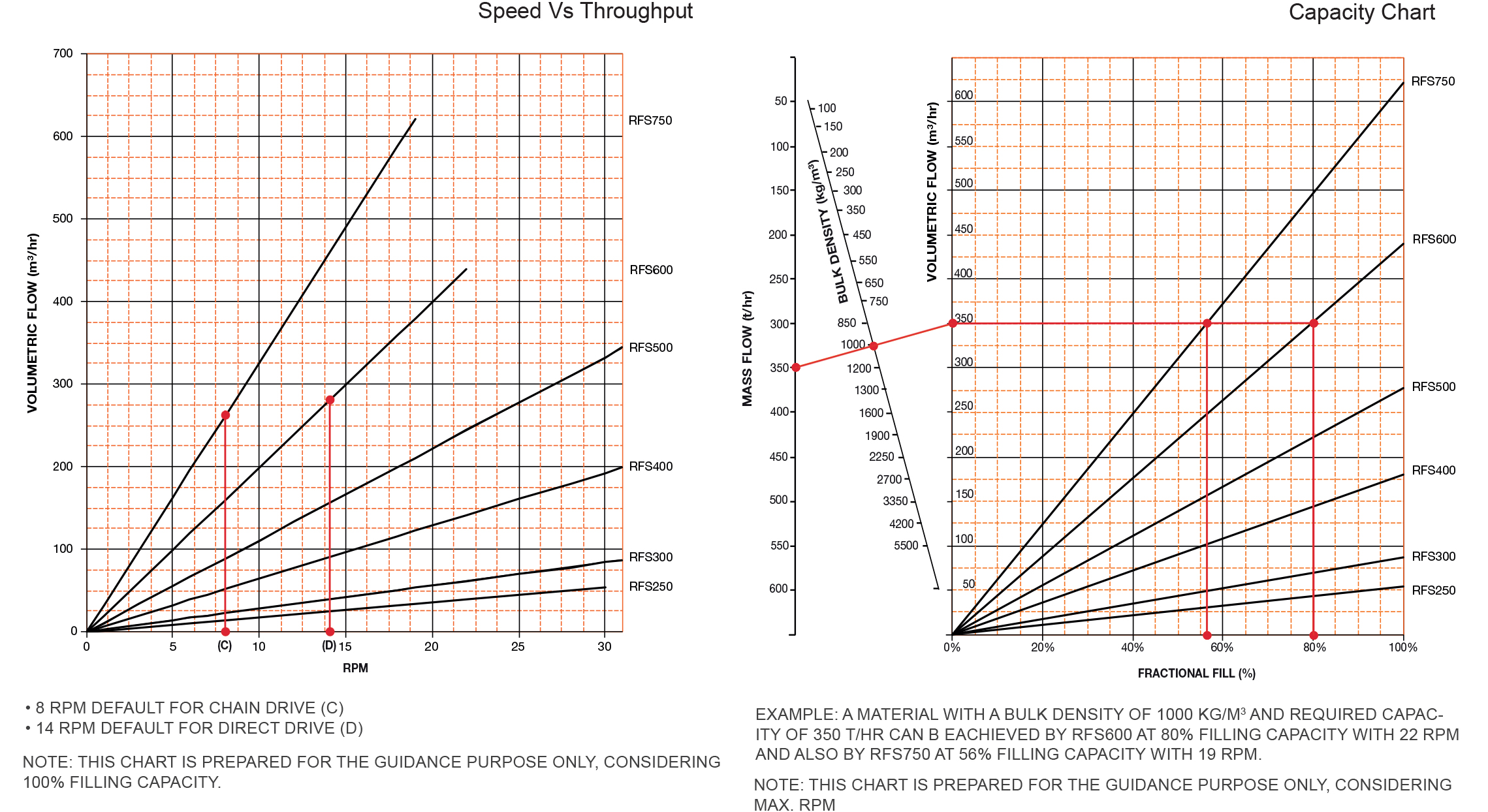

In addition, to Wear Resistance, RFS Valves are best suited to handle High Pressure and High-Temperature applications. RFS Series Valves are in Single Piece Cast Iron construction and available in opening sizes ranging from 250 mm to 750. These valves are not only robust, rigid and durable but can also be customized to the specific requirements of a given application.

The “labyrinth seals” ensures perfect sealing of rotating shaft thus ensures zero leakage through shaft ends. These labyrinth seals even effective with highly abrasive products and also when there is high pressure across the system. These valves are CE marked and in compliance with the provisions of all applicable Health & Safety Requirements across the globe.

Configure the valve to your application