Description

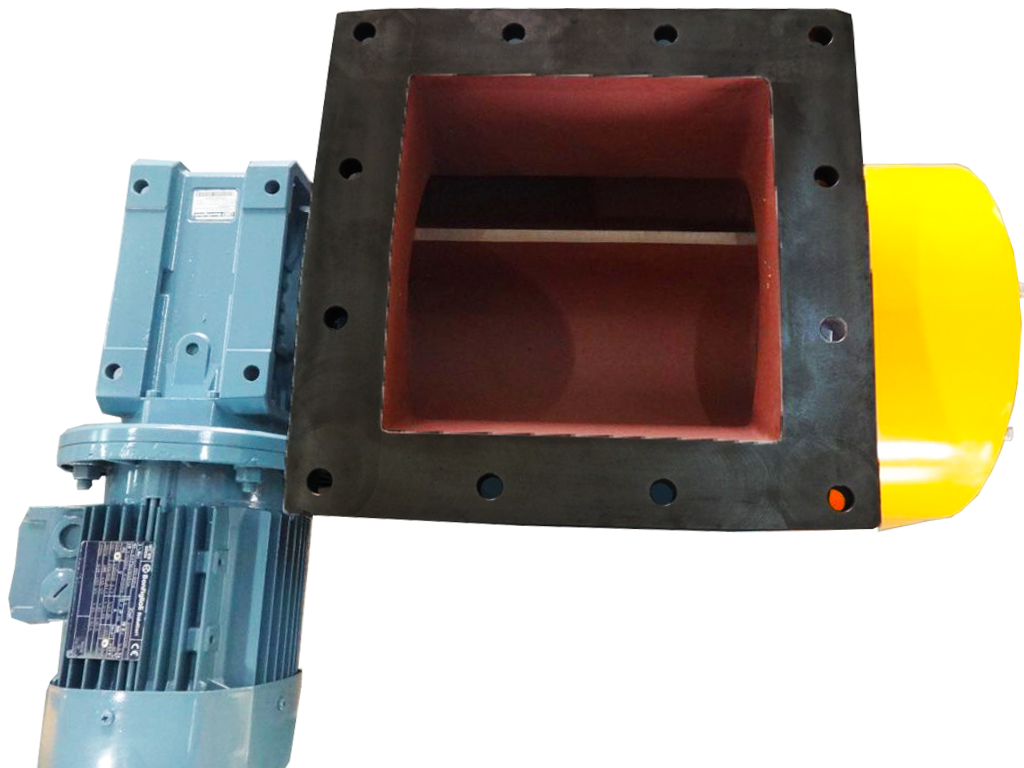

Self cleaning dual rotary Valves to handle Sticky, Viscous, Slow or Non-free flowing bulk solids. While most of the conventional valves could not handle the sticky, viscous and non-flowing bulk solids, Anval RSC Series’ Dual Rotor Valves are well-suited to handle any high-moisture product application.

RSC Series Rotary Valves are complete Cast construction with internal surfaces machined to high precision, ideally suited for animal junk, clay, starch, active ingredients, fertiliser, pulp, fibres, sludge, salt and so on. The self-cleaning function is a result of scraping of the secondary rotor which mechanically empties the pockets of the primary in such a fashion that the secondary and primary rotor movements are synchronised.

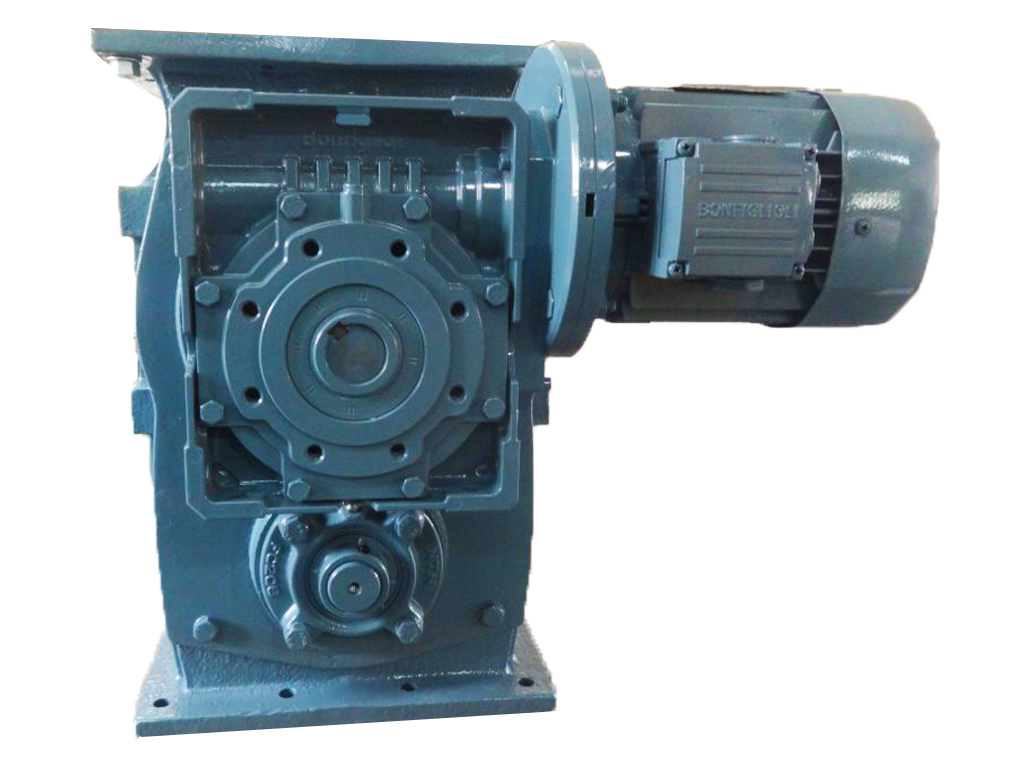

A geared motor drives the primary rotor through the shaft. The secondary rotor drives through a synchronised chain transmission for the easy wiping action on the primary rotor and in turn, pushes the easy flow of material, thus increasing operational efficiency by smoothening material flow and reducing downtime. The “labyrinth seals” ensures perfect sealing of rotating shaft thus ensures zero leakage through shaft ends. These labyrinth seals even effective with highly abrasive products and also when there is high pressure across the system. RSC Series Self cleaning rotary valves are perfectly designed and manufactured to have a close radial and axial clearance for superior air-locking function. The primary rotor comes with a scalloped type as standard. These valves are CE marked and designed in compliance with the provisions of all applicable Machinery Directive requirements.

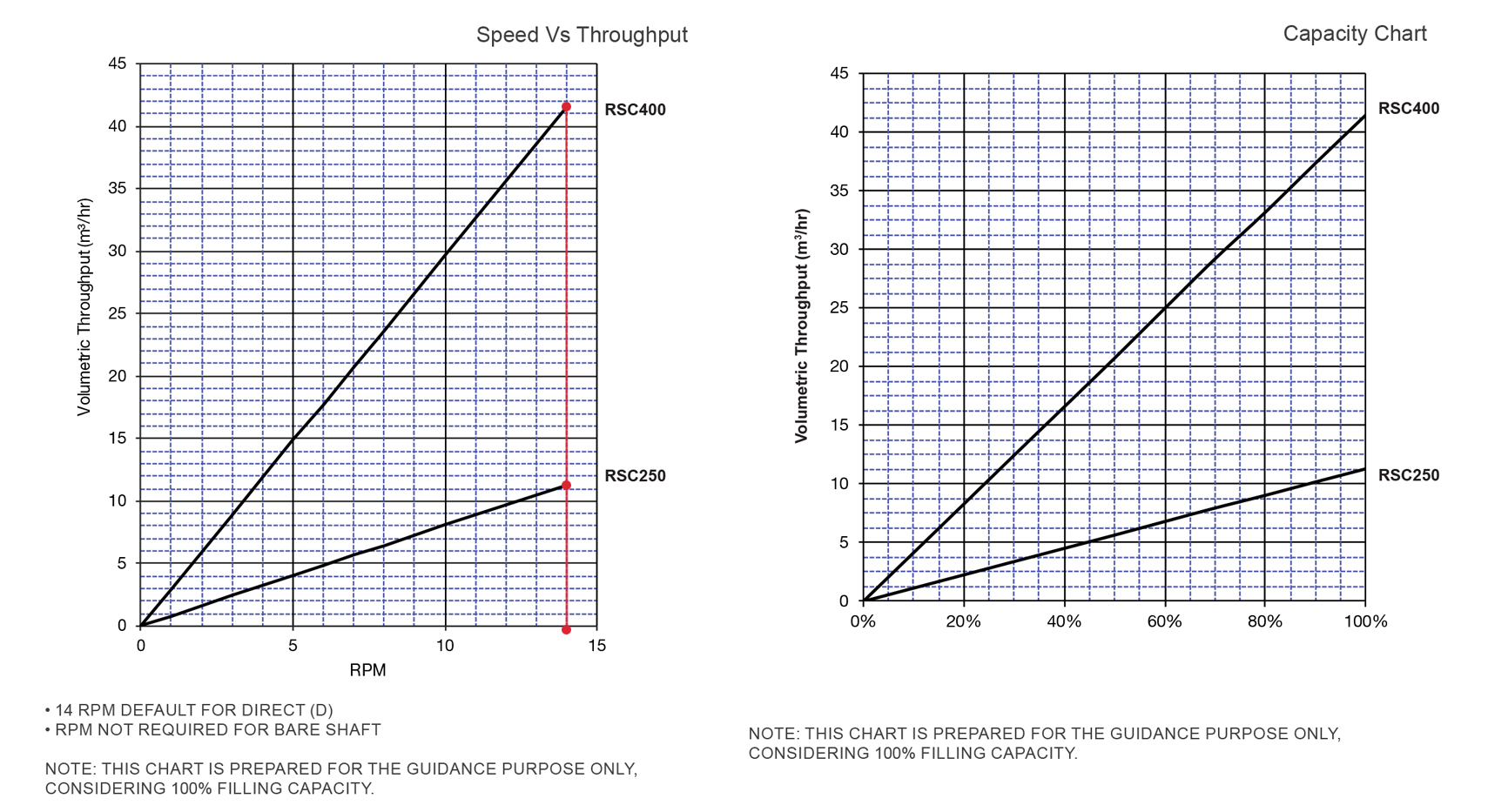

Configure the valve to your application